Benefits of Using Chemical-Resistant SiC Membranes in Filtration Processes

Filtration is a crucial process in various industries, including pharmaceuticals, food and beverage, and wastewater treatment. The efficiency and effectiveness of filtration systems depend on the quality of the membranes used. Chemical-resistant SiC membranes have emerged as a popular choice for filtration processes due to their superior properties and durability.

One of the key benefits of using chemical-resistant SiC membranes is their resistance to harsh chemicals. In industries where corrosive substances are present, such as the chemical and petrochemical industries, traditional membranes may degrade over time, leading to decreased filtration efficiency and increased maintenance costs. SiC membranes, on the other hand, are highly resistant to a wide range of chemicals, including acids, bases, and organic solvents. This resistance ensures that the membranes maintain their integrity and performance even in the presence of aggressive chemicals, resulting in longer membrane lifespan and reduced downtime.

In addition to their chemical resistance, SiC membranes also offer excellent thermal stability. High temperatures can have a detrimental effect on the performance of filtration membranes, causing them to deform or lose their filtration properties. SiC membranes can withstand extreme temperatures, making them ideal for applications where high temperatures are involved, such as in the pharmaceutical and food industries. Their thermal stability ensures consistent filtration performance even under challenging operating conditions, leading to improved process efficiency and product quality.

Another advantage of using chemical-resistant SiC membranes is their mechanical strength. Traditional membranes are prone to breakage and damage, especially in high-pressure filtration systems. SiC membranes are known for their exceptional mechanical properties, including high tensile strength and hardness. This makes them highly resistant to mechanical stress and pressure, reducing the risk of membrane failure and ensuring reliable filtration performance. The robust nature of SiC membranes also makes them suitable for demanding applications, such as wastewater treatment and industrial filtration.

Furthermore, SiC membranes offer excellent fouling resistance. Fouling, or the accumulation of particles and contaminants on the membrane surface, can significantly reduce filtration efficiency and increase operating costs. SiC membranes have a smooth and non-porous surface that inhibits fouling, allowing for continuous and uninterrupted filtration. Their fouling resistance minimizes the need for frequent cleaning and maintenance, resulting in lower operating costs and improved process reliability.

Overall, the use of chemical-resistant SiC membranes in filtration processes offers numerous benefits, including superior chemical resistance, thermal stability, mechanical strength, and fouling resistance. These properties make SiC membranes an ideal choice for industries that require reliable and efficient filtration systems. By investing in SiC membranes, companies can enhance their filtration processes, reduce maintenance costs, and improve overall operational efficiency. As the demand for high-performance filtration solutions continues to grow, chemical-resistant SiC membranes are poised to play a key role in meeting the needs of diverse industries.

Applications of Chemical-Resistant SiC Membranes in Various Industries

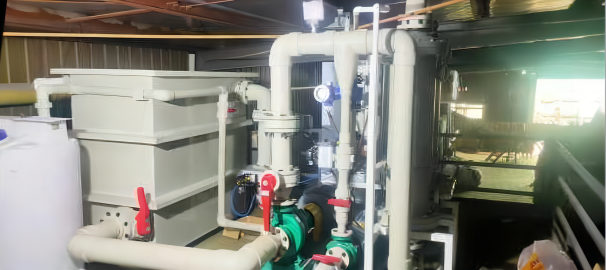

Chemical-resistant SiC membranes play a crucial role in various industries where filtration is essential. These membranes are made from silicon carbide, a material known for its exceptional chemical resistance and durability. In industries such as pharmaceuticals, food and beverage, water treatment, and petrochemicals, the use of SiC membranes ensures efficient and reliable filtration processes.

One of the key advantages of chemical-resistant SiC membranes is their ability to withstand harsh chemicals and high temperatures. This makes them ideal for applications where traditional membranes would degrade or fail. In the pharmaceutical industry, for example, SiC membranes are used to filter out impurities and contaminants from drug formulations. Their chemical resistance ensures that the purity and quality of the final product are maintained.

In the food and beverage industry, SiC membranes are used for the filtration of beverages, dairy products, and other liquid foods. These membranes are resistant to acids, alkalis, and organic solvents, making them suitable for a wide range of applications. They help to remove impurities, bacteria, and other contaminants from food products, ensuring that they meet the highest standards of quality and safety.

In the water treatment industry, chemical-resistant SiC membranes are used for the purification of drinking water, wastewater treatment, and desalination. These membranes are capable of removing a wide range of contaminants, including bacteria, viruses, and heavy metals. Their chemical resistance allows them to operate in harsh environments without degradation, ensuring long-term performance and reliability.

In the petrochemical industry, SiC membranes are used for the filtration of oil, gas, and other hydrocarbons. These membranes are resistant to corrosive chemicals and high temperatures, making them ideal for separating impurities and contaminants from hydrocarbon streams. They help to improve the efficiency of refining processes and ensure the quality of the final products.

Overall, the use of chemical-resistant SiC membranes in various industries offers numerous benefits, including improved filtration efficiency, reduced maintenance costs, and enhanced product quality. These membranes are designed to withstand the most challenging operating conditions, making them a reliable choice for critical filtration applications.

In conclusion, chemical-resistant SiC membranes play a vital role in filtration processes across a wide range of industries. Their exceptional chemical resistance, durability, and reliability make them an ideal choice for applications where traditional membranes would fail. By using SiC membranes, industries can ensure the quality and safety of their products, improve process efficiency, and reduce maintenance costs. As technology continues to advance, the demand for chemical-resistant SiC membranes is expected to grow, further highlighting their importance in modern filtration systems.

Future Developments and Innovations in Chemical-Resistant SiC Membranes for Improved Filtration Performance

Filtration is a critical process in various industries, including water treatment, pharmaceuticals, and food and beverage production. The efficiency and effectiveness of filtration systems depend on the quality of the membranes used. Chemical-resistant membranes are particularly important in industries where harsh chemicals are present, as they can withstand exposure to corrosive substances without deteriorating.

One material that has gained popularity in recent years for its chemical resistance and durability is silicon carbide (SiC). SiC membranes offer several advantages over traditional materials like polymeric membranes, including higher chemical resistance, thermal stability, and mechanical strength. These properties make SiC membranes ideal for applications where exposure to aggressive chemicals is common.

One of the key benefits of using SiC membranes in filtration systems is their ability to maintain their performance over a longer period of time. Traditional polymeric membranes can degrade quickly when exposed to harsh chemicals, leading to a decrease in filtration efficiency and an increase in maintenance costs. SiC membranes, on the other hand, are highly resistant to corrosion and can withstand prolonged exposure to a wide range of chemicals without losing their integrity.

In addition to their chemical resistance, SiC membranes also offer superior filtration performance. The unique structure of SiC membranes allows for precise control over pore size and distribution, resulting in more efficient separation of particles and contaminants from the feed solution. This leads to higher filtration rates and improved product quality, making SiC membranes a preferred choice for industries that require high-purity filtration.

As the demand for more efficient and reliable filtration systems continues to grow, researchers and manufacturers are constantly looking for ways to improve the performance of SiC membranes. One area of focus is the development of advanced surface coatings that further enhance the chemical resistance and filtration properties of SiC membranes. These coatings can provide additional protection against fouling and scaling, prolonging the lifespan of the membranes and reducing maintenance requirements.

Another area of innovation in SiC membrane technology is the integration of nanomaterials to enhance filtration performance. By incorporating nanoparticles into the membrane structure, researchers can create membranes with improved selectivity and permeability, allowing for more precise separation of particles and contaminants. This can lead to higher filtration efficiency and reduced energy consumption, making SiC membranes an even more attractive option for industries looking to optimize their filtration processes.

In conclusion, the importance of chemical-resistant SiC membranes in filtration cannot be overstated. These membranes offer superior chemical resistance, durability, and filtration performance compared to traditional materials, making them an ideal choice for industries that require reliable and efficient filtration systems. With ongoing research and development efforts focused on enhancing the properties of SiC membranes, we can expect to see continued advancements in filtration technology that will benefit a wide range of industries in the future.