Benefits of Using High-Performance Membrane Housings

High-performance membrane housings are an essential component in water treatment systems, providing a secure and efficient environment for membranes to operate at their best. These housings are designed to withstand high pressures and temperatures, ensuring that the membranes inside can perform optimally without any risk of damage or failure. In this article, we will explore the benefits of using high-performance membrane housings in water treatment systems.

One of the key benefits of using high-performance membrane housings is their durability. These housings are typically made from high-quality materials such as stainless steel or fiberglass-reinforced plastic, which are able to withstand the harsh conditions often found in water treatment systems. This durability ensures that the membranes inside are protected from any external factors that could potentially damage them, allowing them to operate at their full capacity for longer periods of time.

In addition to their durability, high-performance membrane housings also offer superior performance. These housings are designed to provide a tight seal around the membranes, preventing any leaks or bypasses that could compromise the quality of the treated water. This tight seal also helps to maintain the pressure inside the housing, ensuring that the membranes are able to function efficiently and effectively.

Furthermore, high-performance membrane housings are designed to be easy to install and maintain. These housings are typically equipped with quick-connect fittings and easy-to-access ports, making it simple for operators to install and replace membranes as needed. This ease of maintenance helps to minimize downtime and ensure that the water treatment system is able to operate continuously without any interruptions.

Another benefit of using high-performance membrane housings is their versatility. These housings are available in a wide range of sizes and configurations, making it easy to find the perfect housing for any water treatment system. Whether you are treating a small residential water supply or a large industrial wastewater stream, there is a high-performance membrane housing that is suitable for your needs.

High-performance membrane housings also offer cost savings in the long run. While these housings may have a higher upfront cost compared to standard housings, their durability and performance ensure that they will last longer and require less frequent replacement. This can result in significant savings over time, making high-performance membrane housings a smart investment for any water treatment system.

In conclusion, high-performance membrane housings offer a wide range of benefits for water treatment systems. From their durability and superior performance to their ease of installation and maintenance, these housings are an essential component for ensuring seamless operations. By investing in high-performance membrane housings, operators can enjoy reliable and efficient water treatment processes that deliver high-quality results consistently.

Key Features to Look for in High-Performance Membrane Housings

High-performance membrane housings are essential components in water treatment systems, as they play a crucial role in ensuring the efficiency and effectiveness of the membrane filtration process. When it comes to selecting membrane housings for your water treatment system, there are several key features that you should look for to ensure seamless operations and optimal performance.

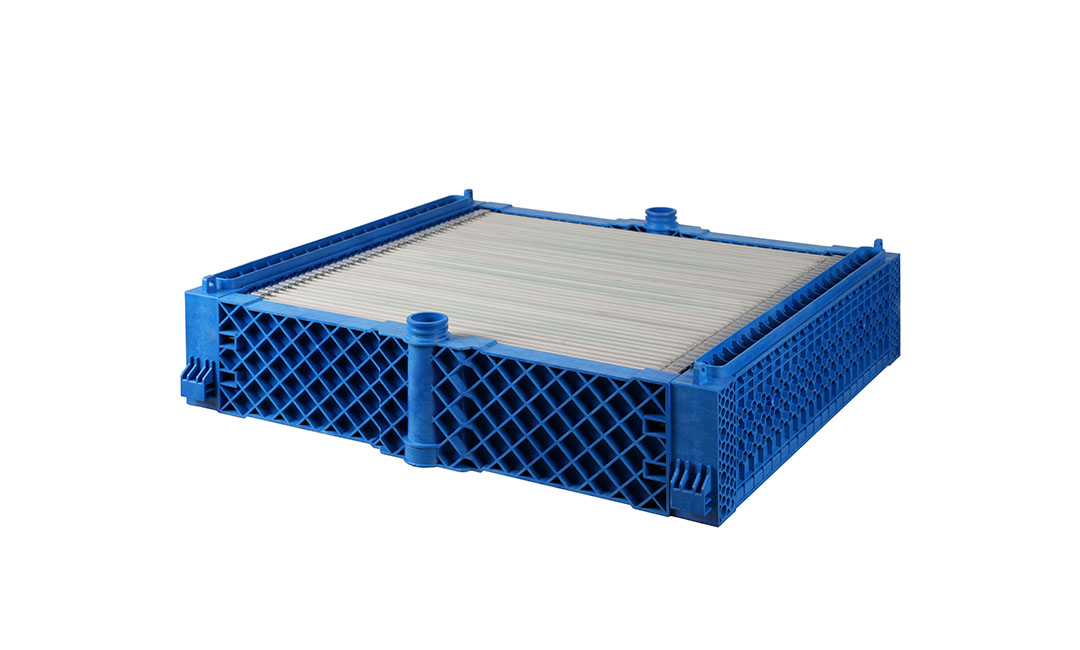

One of the most important features to consider when choosing high-performance membrane housings is the material of construction. Membrane housings are typically made from materials such as fiberglass, stainless steel, or PVC. Each material has its own set of advantages and disadvantages, so it is important to choose a material that is compatible with the specific requirements of your water treatment system. For example, stainless steel membrane housings are known for their durability and resistance to corrosion, making them ideal for use in harsh industrial environments.

Another key feature to look for in high-performance membrane housings is the design of the housing itself. The design of the housing can have a significant impact on the performance of the membrane filtration process. Look for membrane housings that are designed to minimize pressure drop and turbulence, as these factors can affect the efficiency of the filtration process. Additionally, consider the size and configuration of the housing, as this can impact the overall footprint of your water treatment system.

In addition to material and design, it is also important to consider the pressure rating of the membrane housing. The pressure rating of the housing should be compatible with the operating pressure of your water treatment system to ensure safe and efficient operations. High-performance membrane housings are typically designed to withstand high pressures, making them suitable for use in a wide range of applications.

When selecting high-performance membrane housings, it is also important to consider the compatibility of the housing with the membrane elements. Membrane housings are designed to hold membrane elements in place and provide a seal to prevent leakage. Ensure that the housing is compatible with the specific type and size of membrane elements that you plan to use in your water treatment system.

Furthermore, consider the ease of installation and maintenance when choosing high-performance membrane housings. Look for housings that are easy to install and require minimal maintenance to ensure smooth operations and minimize downtime. Some membrane housings are designed with quick-connect fittings and easy-to-access components, making them easier to install and maintain.

In conclusion, high-performance membrane housings are essential components in water treatment systems, and selecting the right housing is crucial for ensuring seamless operations and optimal performance. When choosing membrane housings, consider key features such as material of construction, design, pressure rating, compatibility with membrane elements, and ease of installation and maintenance. By carefully evaluating these features, you can select high-performance membrane housings that meet the specific requirements of your water treatment system and help you achieve efficient and effective membrane filtration.

Case Studies Highlighting Successful Implementation of High-Performance Membrane Housings

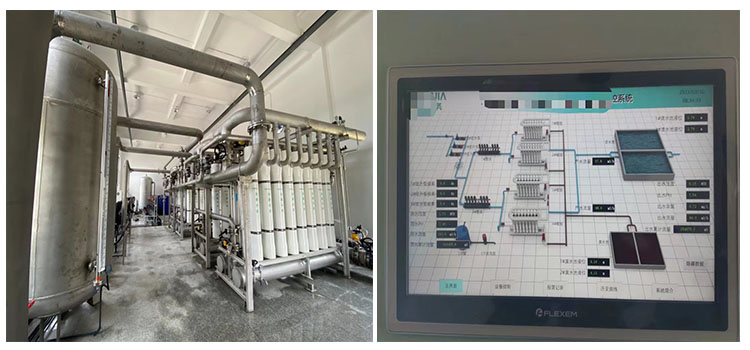

High-performance membrane housings are essential components in water treatment systems, ensuring the efficient operation of membrane filtration processes. These housings play a crucial role in maintaining the integrity of the membranes and maximizing their performance. In this article, we will explore some case studies that highlight the successful implementation of high-performance membrane housings in various water treatment applications.

One of the key benefits of high-performance membrane housings is their ability to withstand high pressures and temperatures, making them ideal for demanding water treatment processes. In a recent case study, a municipal water treatment plant in a large city upgraded its membrane filtration system with high-performance housings to improve the efficiency and reliability of its operations. The new housings were able to handle higher operating pressures, resulting in increased water production and reduced downtime.

Another case study involves a desalination plant in a coastal region that implemented high-performance membrane housings to enhance the performance of its reverse osmosis system. By using housings with superior design and materials, the plant was able to achieve higher salt rejection rates and lower energy consumption, leading to significant cost savings and improved water quality.

In a different application, a food and beverage company installed high-performance membrane housings in its water purification system to meet stringent quality standards for its products. The housings provided excellent protection for the membranes, ensuring consistent water quality and minimizing the risk of contamination. As a result, the company was able to maintain high product quality and compliance with regulatory requirements.

The success of these case studies demonstrates the importance of choosing high-performance membrane housings for water treatment applications. These housings are designed to provide superior performance, durability, and reliability, ensuring seamless operations and optimal efficiency. By investing in high-quality housings, water treatment plants can achieve better results, lower operating costs, and improved overall performance.

In addition to their technical advantages, high-performance membrane housings also offer environmental benefits by reducing energy consumption and water wastage. By optimizing the performance of membrane filtration systems, these housings help to conserve resources and minimize the environmental impact of water treatment processes. This makes them a sustainable choice for water treatment plants looking to improve their operations while reducing their carbon footprint.

Overall, the case studies presented in this article highlight the importance of high-performance membrane housings in achieving successful water treatment outcomes. By choosing housings that are designed for high performance and reliability, water treatment plants can enhance their operations, improve water quality, and reduce costs. With the right housings in place, plants can achieve seamless operations and optimal performance, ensuring the efficient and effective treatment of water for various applications.

Maintenance Tips to Ensure Seamless Operations of High-Performance Membrane Housings

High-performance membrane housings are essential components in water treatment systems, playing a crucial role in ensuring the efficiency and effectiveness of the overall process. These housings are designed to hold the membrane elements securely in place while allowing water to flow through them for filtration. To maintain the seamless operations of high-performance membrane housings, it is important to follow proper maintenance tips and procedures.

One of the key maintenance tips for high-performance membrane housings is regular cleaning. Over time, dirt, debris, and other contaminants can build up on the surface of the membrane housing, reducing its efficiency and potentially causing damage. To prevent this, it is important to clean the housing regularly using a mild detergent and a soft brush. This will help to remove any buildup and ensure that the housing continues to function properly.

In addition to regular cleaning, it is also important to inspect the membrane housing for any signs of damage or wear. Cracks, leaks, or other issues can compromise the integrity of the housing and lead to leaks or other problems. By inspecting the housing regularly, you can identify any issues early on and take the necessary steps to address them before they become more serious.

Another important maintenance tip for high-performance membrane housings is to monitor the pressure levels within the system. High pressure can put strain on the housing and the membrane elements, potentially causing damage or reducing their lifespan. By monitoring the pressure levels regularly and making adjustments as needed, you can ensure that the system operates at optimal levels and avoid any potential issues.

It is also important to replace any worn or damaged parts of the membrane housing as needed. Over time, seals, O-rings, and other components can wear out and need to be replaced to maintain the integrity of the housing. By keeping spare parts on hand and replacing them as needed, you can ensure that the housing continues to function properly and avoid any downtime or disruptions in the filtration process.

Proper storage of high-performance membrane housings is also important for maintaining their performance. Housings should be stored in a clean, dry, and well-ventilated area to prevent any damage from moisture or contaminants. Additionally, housings should be stored in a way that prevents them from being crushed or damaged during storage or transportation.

In conclusion, high-performance membrane housings are essential components in water treatment systems, and proper maintenance is key to ensuring their seamless operations. By following the maintenance tips outlined above, you can keep your membrane housings in optimal condition and ensure that your water treatment system continues to operate efficiently and effectively. Regular cleaning, inspection, pressure monitoring, part replacement, and proper storage are all important aspects of maintaining high-performance membrane housings and ensuring the longevity of your water treatment system. By taking the time to properly maintain your membrane housings, you can avoid costly repairs and downtime and keep your system running smoothly for years to come.

Future Trends in High-Performance Membrane Housings for Improved Efficiency

High-performance membrane housings are essential components in water treatment systems, playing a crucial role in ensuring the efficiency and effectiveness of membrane filtration processes. As technology continues to advance, the demand for high-performance membrane housings that can withstand higher pressures, temperatures, and corrosive environments is on the rise. In response to this growing need, manufacturers are constantly innovating and developing new membrane housing designs that offer improved performance and durability.

One of the key trends in high-performance membrane housings is the use of advanced materials that can withstand extreme operating conditions. Traditional membrane housings are typically made from materials such as PVC, stainless steel, or fiberglass-reinforced plastic. While these materials are suitable for many applications, they may not be able to withstand the high pressures and temperatures required for certain industrial processes. To address this limitation, manufacturers are now using materials such as titanium, duplex stainless steel, and high-performance plastics like polyether ether ketone (PEEK) to create membrane housings that can operate at higher pressures and temperatures without compromising performance.

Another trend in high-performance membrane housings is the development of modular designs that allow for easy installation, maintenance, and replacement of membrane elements. Modular membrane housings consist of multiple smaller units that can be easily connected and disconnected, making it easier to scale up or down the capacity of a water treatment system. This modular approach also simplifies maintenance and repair tasks, as individual units can be replaced without having to shut down the entire system. Additionally, modular membrane housings are more cost-effective, as they allow for incremental upgrades and expansions as needed.

In addition to advanced materials and modular designs, manufacturers are also focusing on improving the overall efficiency of membrane housings through innovative features and technologies. For example, some high-performance membrane housings are equipped with advanced sealing systems that minimize the risk of leaks and ensure a tight seal between the membrane elements and the housing. This not only improves the overall performance of the membrane filtration process but also reduces the risk of contamination and downtime.

Furthermore, manufacturers are incorporating smart technologies into high-performance membrane housings to monitor and control various parameters such as pressure, temperature, and flow rates in real-time. This allows operators to optimize the performance of the membrane filtration system, identify potential issues before they escalate, and make informed decisions to improve efficiency and productivity. By leveraging data and analytics, operators can also predict maintenance needs, schedule preventive maintenance tasks, and minimize downtime.

Overall, the future of high-performance membrane housings is bright, with manufacturers continuously pushing the boundaries of innovation to meet the evolving needs of the water treatment industry. By incorporating advanced materials, modular designs, and smart technologies, high-performance membrane housings are poised to deliver seamless operations, improved efficiency, and enhanced performance for a wide range of applications. As technology continues to advance, we can expect to see even more innovative solutions that will further revolutionize the way membrane filtration systems are designed, installed, and operated.