Improved Drug Purification Processes

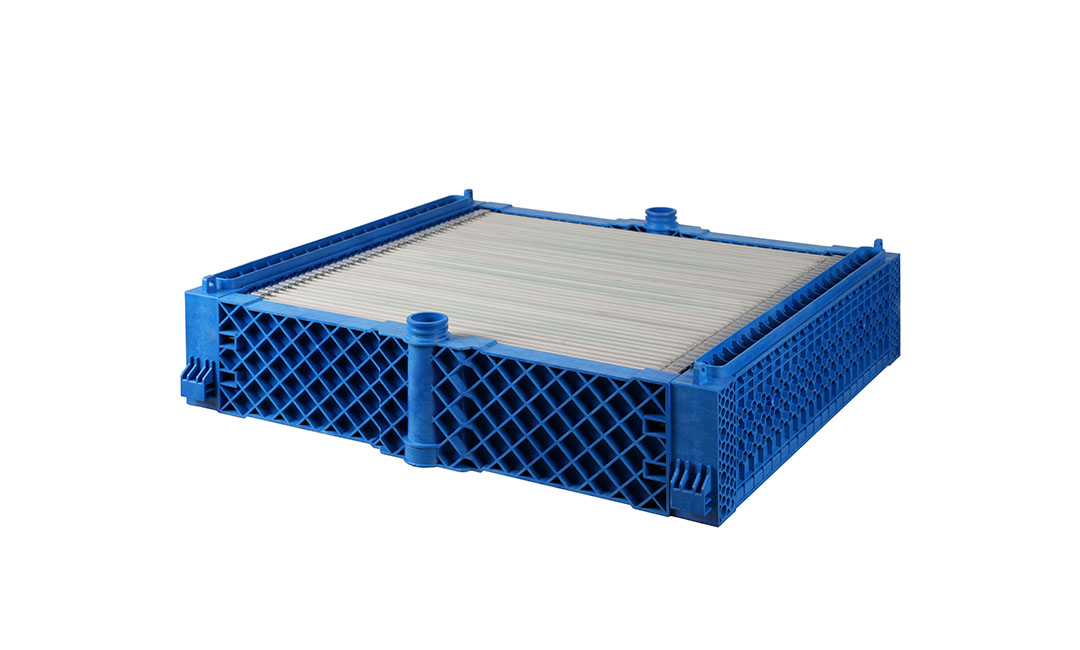

Silicon carbide (SiC) membranes have gained significant attention in the pharmaceutical industry due to their unique properties and applications in improving drug purification processes. These membranes offer several advantages over traditional filtration methods, making them an attractive option for pharmaceutical companies looking to enhance their manufacturing processes.

One of the key benefits of SiC membranes is their high chemical and thermal stability. This allows them to withstand harsh operating conditions, such as high temperatures and aggressive chemicals, without compromising their performance. As a result, SiC membranes can be used in a wide range of pharmaceutical applications, including the purification of drug compounds and the removal of impurities from pharmaceutical products.

In addition to their stability, SiC membranes also offer excellent filtration efficiency. Their unique pore structure allows for precise control over the size and distribution of particles that can pass through the membrane, resulting in highly efficient separation of target molecules from contaminants. This level of precision is crucial in the pharmaceutical industry, where even small impurities can have a significant impact on the quality and efficacy of drugs.

Furthermore, SiC membranes are known for their durability and longevity. Unlike traditional filtration materials, such as polymeric membranes, SiC membranes are highly resistant to fouling and can be easily cleaned and reused multiple times. This not only reduces operating costs for pharmaceutical companies but also minimizes the environmental impact of drug manufacturing processes.

The use of SiC membranes in drug purification processes has been shown to improve the overall quality and purity of pharmaceutical products. By effectively removing impurities and contaminants, SiC membranes help ensure that drugs meet stringent regulatory standards and are safe for human consumption. This is particularly important in the pharmaceutical industry, where product quality and consistency are paramount.

Moreover, SiC membranes can also enhance the efficiency of drug purification processes. Their high filtration rates and low energy consumption make them a cost-effective solution for pharmaceutical companies looking to streamline their manufacturing operations. By reducing processing times and increasing throughput, SiC membranes can help pharmaceutical companies meet growing demand for their products while maintaining high levels of quality and purity.

Overall, the applications of SiC membranes in the pharmaceutical industry are vast and varied. From drug purification to impurity removal, these membranes offer a versatile and reliable solution for pharmaceutical companies looking to improve their manufacturing processes. With their high stability, efficiency, and durability, SiC membranes are poised to play a key role in shaping the future of drug manufacturing and ensuring the safety and efficacy of pharmaceutical products for years to come.

Enhanced Drug Delivery Systems

Silicon carbide (SiC) membranes have gained significant attention in the pharmaceutical industry due to their unique properties and potential applications in enhancing drug delivery systems. These membranes offer several advantages over traditional materials, such as improved chemical resistance, high thermal stability, and excellent mechanical strength. In this article, we will explore the various ways in which SiC membranes can be utilized in the pharmaceutical industry to improve drug delivery systems.

One of the key applications of SiC membranes in the pharmaceutical industry is in the development of controlled release drug delivery systems. These systems are designed to release drugs at a controlled rate over an extended period, allowing for better efficacy and reduced side effects. SiC membranes can be used to create barriers that control the release of drugs, ensuring that the right amount of medication is delivered to the target site at the right time. This can be particularly useful for drugs that have a narrow therapeutic window or require precise dosing.

Another important application of SiC membranes in the pharmaceutical industry is in the filtration and purification of pharmaceutical products. SiC membranes have a high chemical resistance, making them ideal for filtering out impurities and contaminants from drug formulations. These membranes can also be used to separate different components of a drug mixture, allowing for the purification of active pharmaceutical ingredients. By using SiC membranes in the filtration process, pharmaceutical companies can ensure that their products meet the highest quality standards and are free from impurities that could affect their efficacy.

In addition to controlled release systems and filtration applications, SiC membranes can also be used in the development of drug delivery devices. These devices are designed to deliver drugs directly to the target site in the body, bypassing the need for oral or intravenous administration. SiC membranes can be incorporated into these devices to control the release of drugs and ensure that they are delivered in a precise and controlled manner. This can be particularly useful for drugs that have poor solubility or stability, as well as for drugs that need to be delivered to specific tissues or organs.

Furthermore, SiC membranes can also be used in the development of implantable drug delivery systems. These systems are designed to release drugs directly into the body over an extended period, eliminating the need for frequent dosing and improving patient compliance. SiC membranes can be used to create reservoirs that store drugs and release them slowly over time, ensuring a constant and consistent supply of medication. This can be particularly beneficial for patients with chronic conditions who require long-term treatment with medication.

Overall, SiC membranes have a wide range of applications in the pharmaceutical industry, from controlled release systems to filtration and purification processes, as well as drug delivery devices and implantable systems. These membranes offer several advantages over traditional materials, making them an attractive option for pharmaceutical companies looking to improve their drug delivery systems. By incorporating SiC membranes into their processes, pharmaceutical companies can enhance the efficacy, safety, and quality of their products, ultimately benefiting patients and healthcare providers alike.

Sustainable Manufacturing Practices

Silicon carbide (SiC) membranes have gained significant attention in recent years for their potential applications in various industries, including the pharmaceutical sector. These membranes offer several advantages over traditional materials, such as improved chemical resistance, high thermal stability, and excellent mechanical properties. In the pharmaceutical industry, where stringent regulations and quality control are paramount, SiC membranes have the potential to revolutionize manufacturing processes and improve overall efficiency.

One of the key applications of SiC membranes in the pharmaceutical industry is in the filtration of pharmaceutical products. These membranes can effectively remove impurities, bacteria, and other contaminants from liquids, ensuring the purity and safety of the final product. The high chemical resistance of SiC membranes makes them ideal for use in harsh chemical environments, where traditional membranes may degrade or lose their effectiveness over time.

Furthermore, SiC membranes have a high thermal stability, allowing them to withstand high temperatures during sterilization processes. This is crucial in the pharmaceutical industry, where maintaining sterility is essential to prevent contamination and ensure product safety. By using SiC membranes, pharmaceutical manufacturers can streamline their production processes and reduce the risk of product recalls due to contamination issues.

Another important application of SiC membranes in the pharmaceutical industry is in the separation and purification of pharmaceutical compounds. These membranes can be used to separate different components of a mixture based on their size, shape, or charge, allowing for the isolation of specific compounds with high purity and efficiency. This is particularly useful in the production of active pharmaceutical ingredients (APIs), where purity and consistency are critical for the efficacy and safety of the final product.

In addition to filtration and separation applications, SiC membranes can also be used in the recovery and recycling of solvents and other valuable materials in pharmaceutical manufacturing processes. By using membrane technology, pharmaceutical companies can reduce waste generation, minimize environmental impact, and improve overall sustainability. This aligns with the growing trend towards sustainable manufacturing practices in the pharmaceutical industry, where companies are increasingly looking for ways to reduce their carbon footprint and operate in a more environmentally friendly manner.

Overall, the applications of SiC membranes in the pharmaceutical industry are vast and promising. These membranes offer a range of benefits, including improved filtration efficiency, enhanced chemical resistance, and high thermal stability, making them an attractive option for pharmaceutical manufacturers looking to improve their manufacturing processes and ensure product quality and safety. As the demand for high-quality pharmaceutical products continues to grow, the use of SiC membranes is likely to become more widespread, leading to a more sustainable and efficient pharmaceutical industry in the future.