Benefits of Using Advanced Porous Silicon Membranes for Precision Filtration

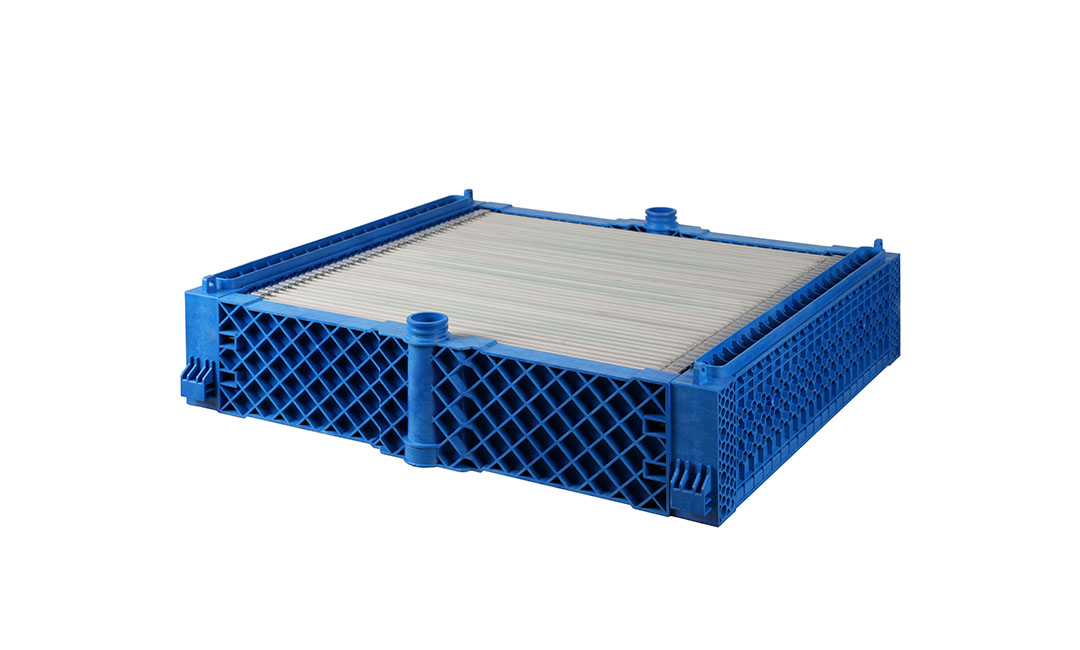

Advanced porous silicon membranes are revolutionizing the field of precision filtration, offering a wide range of benefits that make them an attractive option for various industries. These membranes are designed with intricate pore structures that allow for precise control over the size and shape of particles that can pass through, making them ideal for applications where fine filtration is required.

One of the key benefits of using advanced porous silicon membranes is their high level of customization. These membranes can be tailored to meet specific filtration requirements, allowing for the removal of particles of varying sizes with exceptional accuracy. This level of precision is crucial in industries such as pharmaceuticals, biotechnology, and water treatment, where even the smallest impurities can have a significant impact on product quality.

In addition to their customizable nature, advanced porous silicon membranes also offer excellent durability and longevity. These membranes are highly resistant to chemical corrosion and mechanical stress, ensuring that they can withstand harsh operating conditions without compromising their filtration efficiency. This durability makes them a cost-effective solution for industries that require reliable filtration systems that can operate continuously for extended periods.

Furthermore, advanced porous silicon membranes are known for their high flow rates and low pressure drops, making them energy-efficient and environmentally friendly. By allowing for faster filtration processes with minimal energy consumption, these membranes help reduce operating costs and carbon emissions, making them a sustainable choice for businesses looking to improve their environmental footprint.

Another significant benefit of using advanced porous silicon membranes is their ease of maintenance. Unlike traditional filtration systems that require frequent cleaning and replacement of filter media, these membranes can be easily cleaned and regenerated, extending their lifespan and reducing downtime. This ease of maintenance translates to lower operating costs and increased productivity, making them a valuable investment for businesses looking to streamline their filtration processes.

Moreover, advanced porous silicon membranes offer superior selectivity, allowing for the separation of particles based on their size, shape, and surface properties. This level of selectivity is essential in industries where precise separation of components is required, such as in the production of pharmaceuticals and specialty chemicals. By enabling the separation of particles at the molecular level, these membranes help ensure the purity and quality of the final product.

In conclusion, the benefits of using advanced porous silicon membranes for precision filtration are undeniable. From their high level of customization and durability to their energy efficiency and ease of maintenance, these membranes offer a range of advantages that make them an attractive option for industries looking to improve their filtration processes. With their superior selectivity and reliability, advanced porous silicon membranes are poised to revolutionize the field of precision filtration and drive innovation in a wide range of applications.

Applications of Advanced Porous Silicon Membranes in Various Industries

Porous silicon membranes have emerged as a promising technology for precision filtration in various industries. These advanced membranes offer unique properties that make them ideal for a wide range of applications, from water purification to pharmaceutical manufacturing. In this article, we will explore the diverse uses of advanced porous silicon membranes and their impact on different industries.

One of the key advantages of porous silicon membranes is their high porosity, which allows for efficient filtration of particles and molecules of different sizes. This makes them particularly well-suited for applications where precise separation is required, such as in the pharmaceutical industry. Porous silicon membranes can be used to filter out impurities from drug formulations, ensuring that only the desired active ingredients are present in the final product.

In the biotechnology industry, porous silicon membranes are used for the purification of biomolecules, such as proteins and DNA. The high surface area of these membranes allows for effective adsorption and separation of biomolecules, leading to higher purity and yield in downstream processes. This makes porous silicon membranes an essential tool for researchers and manufacturers working in the field of biotechnology.

Another important application of advanced porous silicon membranes is in water treatment. These membranes can effectively remove contaminants such as bacteria, viruses, and heavy metals from water, making it safe for consumption. This technology has the potential to address the growing global water crisis by providing a cost-effective and sustainable solution for clean drinking water.

In the food and beverage industry, porous silicon membranes are used for the filtration and clarification of liquids such as juices, wines, and dairy products. These membranes can remove suspended particles and microorganisms, improving the quality and shelf life of the final product. By using porous silicon membranes, manufacturers can ensure that their products meet the highest standards of safety and quality.

The electronics industry also benefits from the use of advanced porous silicon membranes. These membranes can be used for the fabrication of microfluidic devices, sensors, and other electronic components. The precise control over pore size and distribution in porous silicon membranes allows for the creation of custom-designed structures with unique properties, making them an essential material for advanced electronic applications.

In the environmental sector, porous silicon membranes are used for the treatment of industrial wastewater and air pollution control. These membranes can effectively remove pollutants and contaminants from industrial effluents, helping to protect the environment and comply with regulatory standards. By using porous silicon membranes, industries can reduce their environmental footprint and contribute to a more sustainable future.

Overall, advanced porous silicon membranes have a wide range of applications in various industries, from pharmaceuticals to electronics to environmental protection. Their unique properties make them an essential tool for precision filtration and separation processes, leading to improved product quality, efficiency, and sustainability. As technology continues to advance, we can expect to see even more innovative uses of porous silicon membranes in the years to come.

How Advanced Porous Silicon Membranes Improve Filtration Efficiency

Advanced porous silicon membranes have revolutionized the field of filtration by offering enhanced precision and efficiency in separating particles from liquids or gases. These membranes are designed with a high degree of porosity, allowing for the selective passage of molecules based on size, shape, or charge. This level of control over the filtration process has led to significant advancements in various industries, including pharmaceuticals, water treatment, and electronics.

One of the key advantages of advanced porous silicon membranes is their ability to achieve precise filtration at the nanoscale level. Traditional filtration methods often struggle to separate particles that are smaller than a few microns in size. However, porous silicon membranes can be engineered to have pore sizes as small as a few nanometers, enabling the filtration of even the tiniest particles with remarkable accuracy.

Moreover, the uniformity of pore size distribution in porous silicon membranes ensures consistent filtration performance across the entire surface area. This uniformity minimizes the risk of clogging or uneven filtration, resulting in a more reliable and efficient filtration process. As a result, industries that require high-purity filtration, such as pharmaceutical manufacturing or semiconductor production, can benefit greatly from the use of advanced porous silicon membranes.

In addition to their precision and uniformity, advanced porous silicon membranes offer excellent chemical and thermal stability. This makes them suitable for a wide range of applications where harsh operating conditions are common. For example, in the field of wastewater treatment, porous silicon membranes can withstand exposure to corrosive chemicals and high temperatures without compromising their filtration efficiency. This durability ensures a longer lifespan for the membranes and reduces the need for frequent replacements, ultimately leading to cost savings for industries that rely on filtration technology.

Furthermore, the customizable nature of porous silicon membranes allows for tailored filtration solutions to meet specific industry requirements. By adjusting parameters such as pore size, surface chemistry, and thickness, manufacturers can optimize the performance of the membranes for different applications. For instance, in the food and beverage industry, porous silicon membranes can be modified to selectively remove contaminants while retaining essential nutrients and flavors in the final product.

Overall, the use of advanced porous silicon membranes has significantly improved filtration efficiency in various industries by offering precise separation, uniform performance, chemical and thermal stability, and customization options. As technology continues to advance, we can expect further innovations in membrane design and fabrication techniques, leading to even greater improvements in filtration processes. With the demand for high-quality filtration solutions on the rise, porous silicon membranes are poised to play a crucial role in meeting the evolving needs of modern industries.

Comparison of Advanced Porous Silicon Membranes with Traditional Filtration Methods

Porous silicon membranes have emerged as a promising technology for precision filtration in various industries. These advanced membranes offer several advantages over traditional filtration methods, making them a preferred choice for applications requiring high efficiency and precision.

One of the key advantages of porous silicon membranes is their tunable pore size. Traditional filtration methods often have fixed pore sizes, limiting their ability to filter particles of different sizes effectively. In contrast, porous silicon membranes can be engineered to have precise pore sizes, allowing for the selective filtration of particles based on their size. This tunability makes porous silicon membranes ideal for applications where precise control over particle size is crucial.

Another advantage of porous silicon membranes is their high porosity. Traditional filtration methods typically have lower porosity, which can lead to clogging and reduced filtration efficiency over time. Porous silicon membranes, on the other hand, have a high porosity that allows for efficient filtration of particles while minimizing clogging. This high porosity also enables faster filtration rates, making porous silicon membranes a more efficient option for applications requiring rapid filtration.

In addition to their tunable pore size and high porosity, porous silicon membranes also offer excellent chemical and thermal stability. Traditional filtration methods may be susceptible to chemical degradation or thermal damage, limiting their lifespan and effectiveness. Porous silicon membranes, however, are highly stable in a wide range of chemical and thermal environments, making them suitable for use in harsh conditions where traditional filtration methods may fail.

Furthermore, porous silicon membranes can be easily integrated into existing filtration systems, making them a cost-effective option for upgrading filtration processes. Traditional filtration methods often require significant modifications to accommodate new technologies, leading to increased costs and downtime. Porous silicon membranes, with their compatibility with existing systems, offer a seamless transition to more advanced filtration capabilities without the need for extensive modifications.

Overall, the comparison between advanced porous silicon membranes and traditional filtration methods highlights the superior performance and versatility of porous silicon membranes in precision filtration applications. With their tunable pore size, high porosity, chemical and thermal stability, and ease of integration, porous silicon membranes offer a more efficient and cost-effective solution for industries requiring precise filtration capabilities.

In conclusion, advanced porous silicon membranes represent a significant advancement in filtration technology, offering a range of benefits over traditional filtration methods. Their tunable pore size, high porosity, chemical and thermal stability, and ease of integration make them a preferred choice for applications requiring precision filtration. As industries continue to demand higher efficiency and performance from their filtration systems, porous silicon membranes are poised to play a crucial role in meeting these requirements.

Future Developments and Trends in Advanced Porous Silicon Membranes for Precision Filtration

Porous silicon membranes have gained significant attention in recent years due to their unique properties and potential applications in precision filtration. These membranes are characterized by their high surface area, tunable pore size, and excellent mechanical stability, making them ideal candidates for various filtration processes. As researchers continue to explore the potential of porous silicon membranes, future developments and trends in this field are expected to drive innovation and enhance the performance of these materials.

One of the key areas of focus in the development of advanced porous silicon membranes is the optimization of pore size and distribution. By controlling the size and distribution of pores within the membrane, researchers can tailor the filtration properties to meet specific requirements. For example, membranes with smaller pore sizes are more effective at filtering out smaller particles, while membranes with larger pore sizes are better suited for high-flow applications. By fine-tuning the pore size and distribution, researchers can optimize the performance of porous silicon membranes for a wide range of filtration tasks.

Another important trend in the development of porous silicon membranes is the integration of advanced surface modifications. Surface modifications can enhance the selectivity and efficiency of the membrane by introducing functional groups or coatings that interact with specific molecules or particles. For example, functionalizing the surface of the membrane with hydrophobic or hydrophilic groups can improve its performance in separating oil and water emulsions. By incorporating advanced surface modifications, researchers can expand the capabilities of porous silicon membranes and address complex filtration challenges.

In addition to pore size optimization and surface modifications, researchers are also exploring novel fabrication techniques to improve the performance of porous silicon membranes. Advanced manufacturing methods, such as electrochemical etching and laser ablation, offer precise control over the structure and properties of the membrane, leading to enhanced filtration efficiency and durability. By leveraging these advanced fabrication techniques, researchers can push the boundaries of porous silicon membrane technology and unlock new possibilities for precision filtration applications.

Furthermore, the integration of smart materials and nanotechnology into porous silicon membranes is a promising avenue for future development. Smart materials, such as responsive polymers or stimuli-responsive nanoparticles, can be incorporated into the membrane to enable dynamic control over its filtration properties. By harnessing the unique properties of smart materials, researchers can design membranes that adapt to changing environmental conditions or specific filtration requirements. Nanotechnology, on the other hand, offers opportunities to enhance the performance of porous silicon membranes at the nanoscale level, enabling precise control over filtration processes and improving overall efficiency.

Overall, the future of advanced porous silicon membranes for precision filtration is bright, with ongoing research and development efforts driving innovation and pushing the boundaries of membrane technology. By focusing on pore size optimization, surface modifications, advanced fabrication techniques, and the integration of smart materials and nanotechnology, researchers are poised to unlock new possibilities for precision filtration applications. As the field continues to evolve, advanced porous silicon membranes are expected to play a key role in addressing complex filtration challenges and advancing the state-of-the-art in membrane technology.